ADF caught up with Jeremy English of Sӧdra to discuss why he feels timber is the solution to the UK’s housing crisis, and how the material can help architects adopt less labour-intensive, offsite building techniques

What do you see as the main challenges facing the UK housing industry?

Government commitments, underpinned by the prospect of Brexit depleting the labour force and an ever-increasing necessity for sustainability, means the housing industry cannot possibly deliver 300,000 new homes a year using traditional building methods alone. The coming years will inevitably see scrutiny turn toward how these houses will be built, how quickly they can be built, and how much money they’re likely to cost. Timber may prove to be the answer that is needed.

So, what’s so special about timber?

First and foremost, timber is the ultimate sustainable building material, which is an important asset given this government’s plans to reduce carbon emissions by 3 per cent each year up until 2050. As trees grow, they naturally absorb harmful carbon dioxide, locking CO2 into the wood rather than releasing it into the atmosphere. Timber’s overall embodied energy is also the lowest of any mainstream building material. This factors in energy expended through building, production and transportation, typically accounting for around 30-50 per cent of a project’s entire carbon footprint. It takes very little energy to convert trees into timber for construction, for example, while the building process typically requires a fifth of the vehicle deliveries demanded by concrete. Aside from this, its insulating properties make buildings cheaper, greener and easier to heat post-construction. Timber is also lightweight, versatile and easy to handle and install – all of which helps reduce construction time by around a third and typically result in less-expensive building. It does sometimes mean that timber is thought of as a weaker form of construction, but that certainly isn’t true. Timber is remarkably strong and durable, guaranteeing that regardless of speedy construction, there’s no compromise in quality.

How do these qualities help facilitate offsite modular housing?

At a time when the construction industry is under increased pressure to build quickly and sustainably, timber offers an often inspirational alternative construction solution. The material’s ability to streamline the offsite manufacturing process can help cut build time by as much as 50 per cent and a timber frame can be precisely pre-cut and easily put together with less manpower, fewer deliveries to site, and minimal debris left behind. Manufacturing in a controlled factory environment also means that the great British weather is never a problem! It’s less likely there will be any defects, risk of injury is reduced, and with greater potential to automate more steps of the manufacturing process, dependence on traditional skilled labour is reduced. All these factors help to cut costs, making timber construction a dramatically more cost-effective form of construction than traditional building methods.

Are we seeing people’s perceptions of timber construction changing in the UK?

Here in the UK timber construction is making great strides. Legal & General, for example, took over 9,000 homes from Richmond Council and committed to building thousands of timber-framed flats and houses offsite for Richmond Housing Partnership (RHP). RHP bought them for at least 15 per cent below the standard cost for onsite construction and is set to rent them out for just £600-£700 per month. This is staggering considering rent for a single-bed flat in the Richmond area typically costs upwards of £1,000. It’s a great example of timber construction being used to help deliver truly affordable homes. We’ve also very recently seen Mayor Sadiq Khan agree to contribute £50,000 to fund a ‘developers’ toolkit’ to help simplify the construction of offsite homes in London. It’s a significant step forward for modular housing in London and represents recognition that modular housing truly can help fix the UK’s ‘broken’ housing market. The case for timber outside the capital is also strong. Lovell, Morgan Sindall’s housebuilding arm, has recently signed a £45m modular housing deal with Homes England under the Government’s Accelerated Construction initiative. 200 homes will be built with modular closed panel, pre-insulated timber frames and roof cassettes in Leyland, Lancashire. Lovell has said that this method could double the speed of construction. There is, however, still work to be done. Timber frame construction currently accounts for a massive 76 per cent of housebuilding in Scotland, but just a quarter of housebuilding in England and Wales. Factory-based construction was up 15 per cent in Germany and Japan last year and structural timber exports to the US are expected to continue increasing. With timber already leading the way in other parts of the world, the UK must step up its use of timber to help achieve its own housebuilding objectives.

What potential obstacles are there to the progress of modular homes?

Although modular homes are typically less expensive than traditional building methods, acquiring sites and constructing the factories to put them together can be costly, which may mean we see a somewhat slower uptake from certain housebuilders and developers. Legal & General (L&G), however, spurred on from last year’s Autumn Budget, has looked to accelerate its housebuilding having already launched a £55m offsite housing factory in Yorkshire in 2016. It is the largest housebuilding factory in Europe and subsequently delivered homes to the Richmond Housing Partnership discussed earlier. James Lidgate, L&G Homes CEO commented that its multi-tenure approach to housebuilding could help them “achieve a 50 per cent improvement in delivery,” suggesting that eventual housebuilding capability more than makes up for the initial expense.

What benefits does timber offer architects?

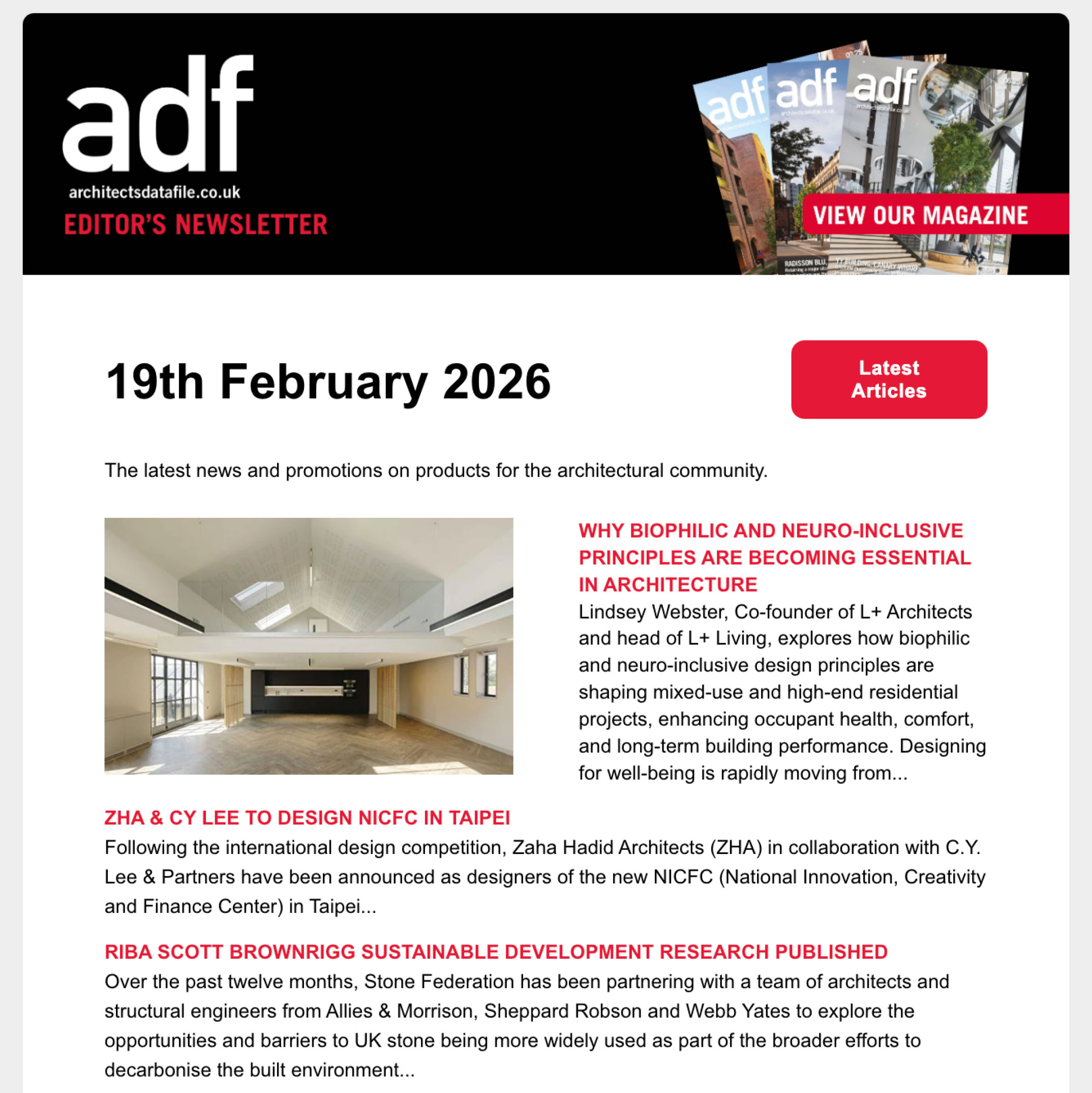

Timber’s natural beauty and versatility is hard to replicate, and a timber-framed building can provide a highly desirable aesthetic. Timber naturally grows more slowly in colder climates, resulting in a tighter grain and growth rings, which not only signifies better stability and greater strength, it also provides an additional aesthetic feature. And, if you’re working with timber that will be exposed and on show, it offers a wide range of aesthetics that give great design flexibility. It can vary in colour and texture, be painted in any colour, waxed and varnished, carved, cut, glued and nailed – or just left as it is. It can also be clad in external materials, allowing it to complement specific local regulations and planning requirements. It’s no surprise that we’re seeing more and more timber structures being built. It’s a great selling point for eventual occupants to know that their home or office has not damaged the environment but has in fact locked in and helped mitigate the effects of otherwise potentially harmful carbon dioxide. Speed and ease of construction are also two key benefits. Waugh Thistleton Architects, for example, has long championed sustainable timber construction and put together Murray Grove and Dalston Lane – two landmark projects. Nine-storey Murray Grove was the first tall urban housing project to be constructed entirely from pre-fabricated solid timber and was put up by a team of four in just 27 days. Dalston Lane required just 111 deliveries of materials during construction, compared with over 700 deliveries on a typical concrete and steel project. And earlier this year, Sumitomo Forestry revealed plans to build W350 – a 70-storey, 350-metre timber skyscraper in Tokyo. W350 would become the world’s tallest timber structure and the tallest building in Japan. Projects like these not only help raise the profile of timber construction, but also offer all the evidence and reassurance people need that timber is the building material of the future.

Jeremy English is sales director at Sӧdra – Sweden’s largest forest-owner association