Tony Stevens at Bilco UK explains ‘NSHEVs’ – a ‘natural’ approach to ventilating spaces during fires – and factors that architects need to address when considering it

According to The National Statistics Survey for fire and rescue services in England, smoke inhalation is the leading cause of death in fires, and was responsible for 34% of fire-related deaths in 2018/2019. As an architect or specifier, ensuring the right Natural Smoke and Heat Exhaust Ventilator (NSHEV) is installed is paramount to ensuring the product is fit for purpose for the chosen application, and provides the highest levels of safety and compliance.

Understanding the importance of NSHEVs

It is a specifier’s responsibility to ensure that the correct product is used in the right context and is manufactured to the highest quality, affirming the safety of the building for its entire lifecycle.

When a fire ignites in an enclosed space, the smoke rising from the fire gets trapped by the ceiling. It then begins to spread, forming an expanding layer that leaks into any gaps in the floors or walls. This can lead to individuals becoming disorientated, and their vision becoming increasingly impaired, hindering safe evacuation.

NSHEVs protect building occupants by preventing the excessive build-up of smoke and noxious fumes by exhausting the smoke quickly and safely. This reduces the risk of smoke inhalation and damage, horizontal fire spread and secondary ignitions. In the event of a fire, units also improve visibility, accelerating evacuation times and assisting firefighters.

Ensuring constant compliance

When specifying a NSHEV, it should be fully compliant with the Construction Products Regulation 305/2011, CE-marked with a Declaration of Conformity and manufactured to meet the demands of Building Regulations, Approved Document B, BS9999 and BS EN12101-2.

Choosing a smoke vent that meets all of these legislations will help to not only achieve compliance, but ensure the operational reliability and performance of the installation throughout its lifetime.

Customising the design

While ensuring compliance and safety is paramount, there are additional aspects that need to be considered as part of the specification process. There are many options to consider when specifying, from aesthetics, to operations and smoke control. When considering smoke control, it’s advised to be in the form of a dedicated management system, or a solution integrated into a wider networked fire alarm system.

A choice of hardware, paint finishes, kerb liners, manual and automated control units, open-close switches and rain and wind sensors can also result in the creation of a customised NSHEV, which can ensure the product is fit for purpose for the particular installation environment.

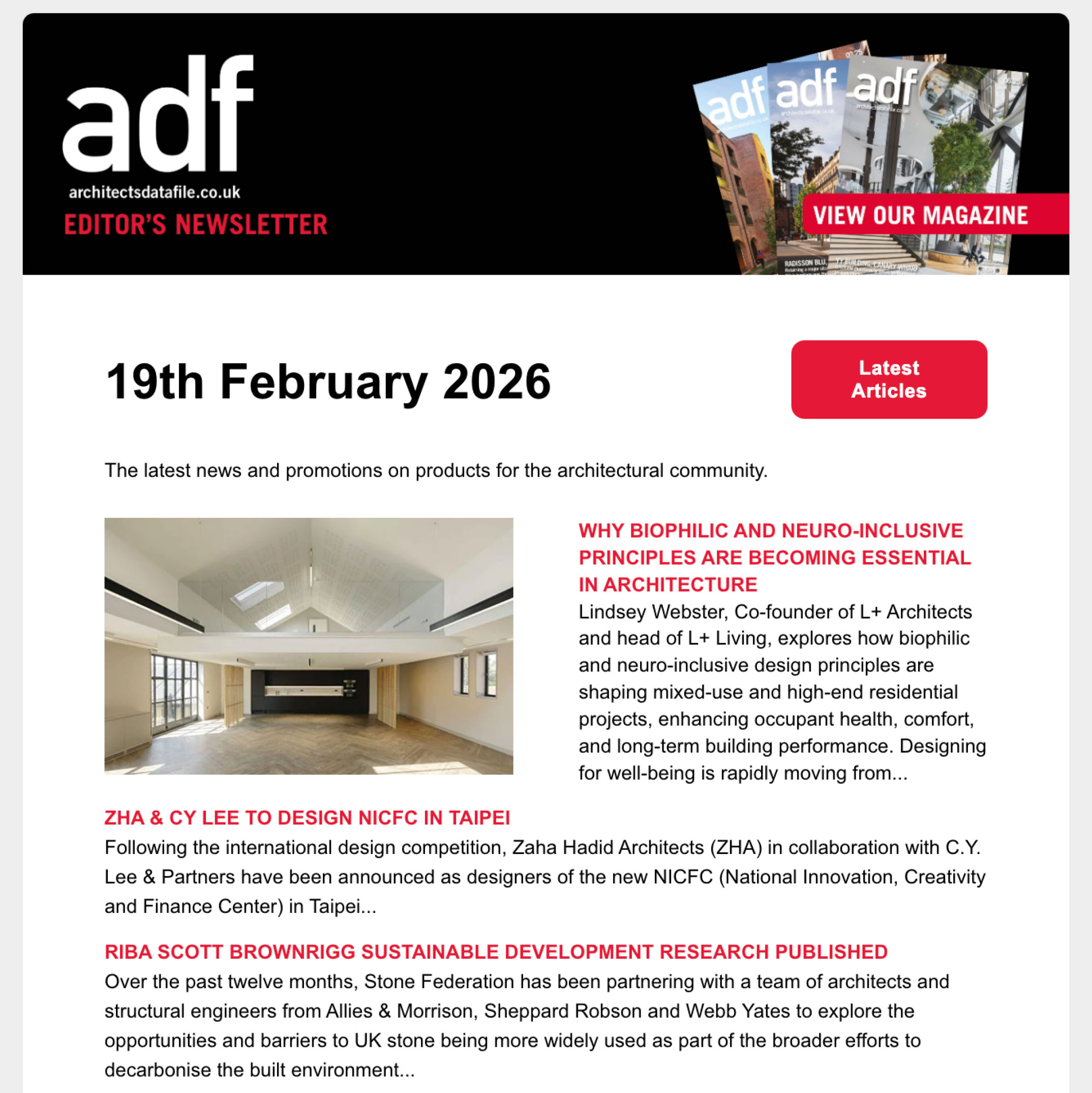

With some simple modifications, such as the addition of a fixed vertical safety ladder, a unit can also provide a means of escape from the roof, or offer access for infrequent maintenance. By using a skylight, the NSHEV can also offer a source of natural daylight to the space below.

Product in practice

Discovering the need for reliable smoke ventilation with a bold yet discreet design, the Riverside Museum in Glasgow required two custom-designed smoke vents to meet strict requirements with regard to building safety regulations.

The museum’s iconic design dominates its riverside location, while paying homage to the heritage of its surroundings. Crucial to the museum’s flowing design is its roof, which curves and undulates and continues around the east and west sides of the building to constitute the majority of the external structure.

The smoke vents were manufactured to a unique specification to create a seamless, aesthetic finish with the museum’s distinctive roof, showing that style can also be accomplished alongside safety.

The ideas of smoke clearance and smoke ventilation, like many other fire safety systems, can be complex. However, as ‘life-safety’ systems, they must be robust and durable, and tested to the industry standard. The design and equipment must be suited to the building type, and installation and maintenance must be done by a highly qualified team to ensure that the systems function effectively when needed.

Tony Stevens is technical estimator at Bilco UK