When approaching the refurbishment of industrial or warehousing units; the rooflights should always be a key priority. While light levels can be increased through maintenance and cleaning; GRP rooflights typically carry a 30-year service life (with some much lower); this means that at the time of refurbishment it is likely that the rooflights will need to be completely replaced.

Hambleside Danelaw were invited to the site of a manufacturing facility which was desperately needing a face-lift. With decades in the industry, it is rare that the Zenon team are unable to identify the rooflights, but these grime-covered single-skin barrel vaults were beyond recognition, having undergone years of weathering in rainy Preston.

Paul Hanratty, National Sales Manager for Zenon GRP Rooflights stated:

“It’s very often simply not possible to determine the non-fragility status of older roof assemblies. This is also true of the rooflights installed in them. Lack of cleaning and maintenance, emissions from surrounding businesses which simply did not exist when the building was erected, poorly executed ‘repairs’, and expired design-life guarantees, can all affect the performance and status of older roofs and rooflights. A well-documented inspection and maintenance programme can help to keep rooflights performing as intended throughout their design life, saving energy and money, and safeguarding the wellbeing of anyone who needs to traffic the roof.”

‘Unusual’ is a key word in this refurbishment job – with approximately 143 runs of rooflights needing replacing, the lengths varied significantly throughout the roofscape. Positioning of these rooflights was also unusual, with some barrel vaults positions mid-slope as one would expect, and others terminating upslope at the ridge, interrupting the flashing.

BBR Roofing, the contractors for this project, removed the weathersheet to allow Hambleside Danelaw to look inside a downslope barrel vault. To their surprise the opening revealed solid metal. The internal sheet started further upslope – despite the rooflight weathersheet beginning much further down!

Jim Bauress, Contracts Manager at BBR Roofing stated:

“We are extremely pleased with the Zenon Arc rooflights. The Zenon team provided great solutions for our specific requirements on this huge refurbishment project. The natural daylight provided by these rooflights make a real difference to the lighting within the building and creates a more effective working environment.’’

The Zenon team, after scratching their heads, picked up their pencils and got to work. Due to the already existing ‘bones’ of the unit, some of the mixed bag of lengths would have to remain. It was decided that the point at which the rooflights terminated on the downslope would have to remain. However, Zenon were able to incorporate apron flashings into the design of the roofscape to allow for a more uniformity in some run lengths.

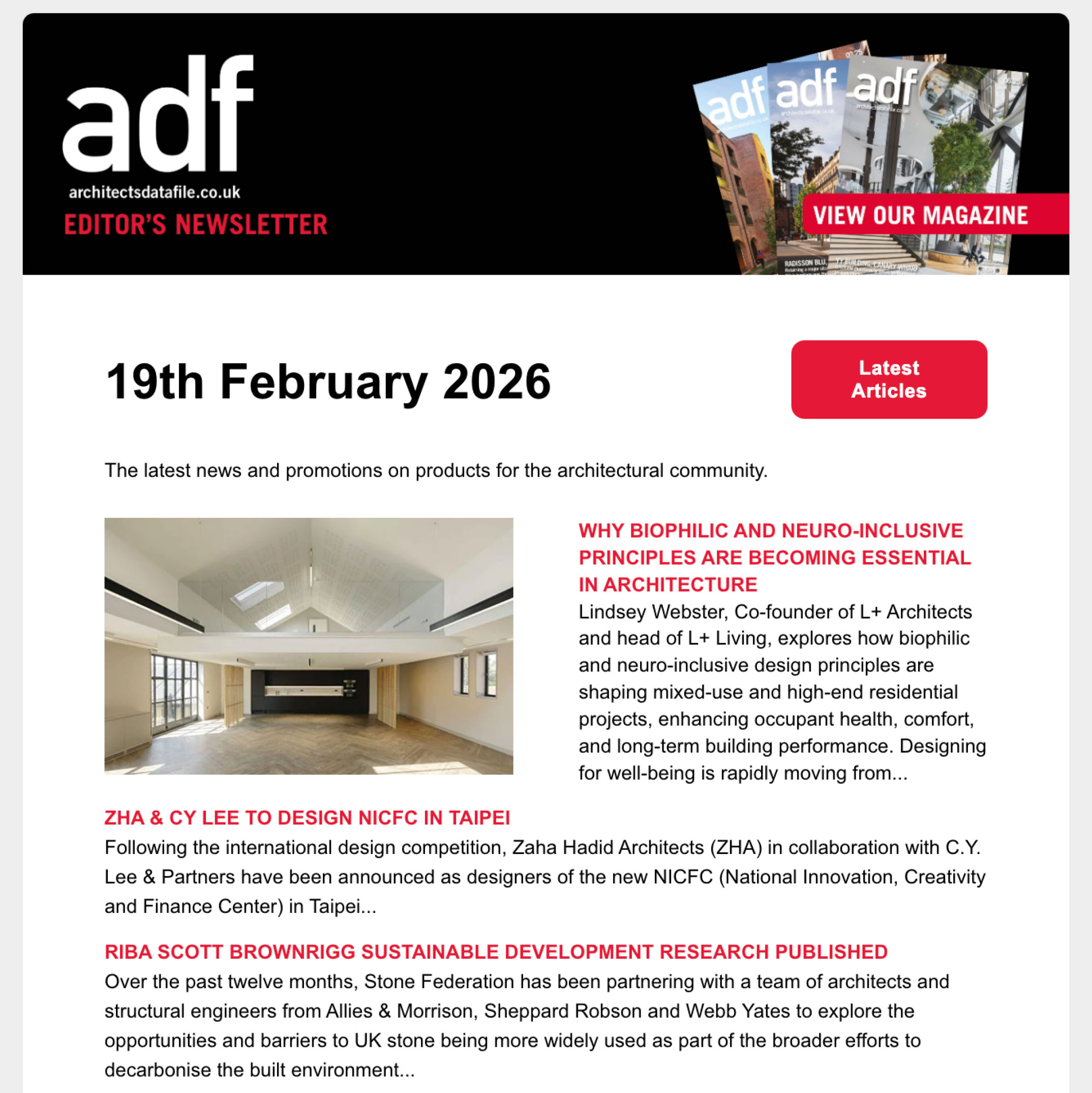

This was the largest single unit of barrel vault rooflights that Zenon have produced – 1740 linear metres, 143 runs, and days of production work. The varying lengths required a herculean effort to organise and check off. With all this in mind, Hambleside Danelaw thought it was the perfect opportunity to take to the skies.

Alongside some stunning scenery, the roof of this unit has never looked so good! And with the installation of Zenon Arc barrel vault rooflights, the occupants can expect 66% light transmission – a bit more daylight than previously.

To learn more about Zenon GRP rooflights, please get in touch with our team on 01327 701910.