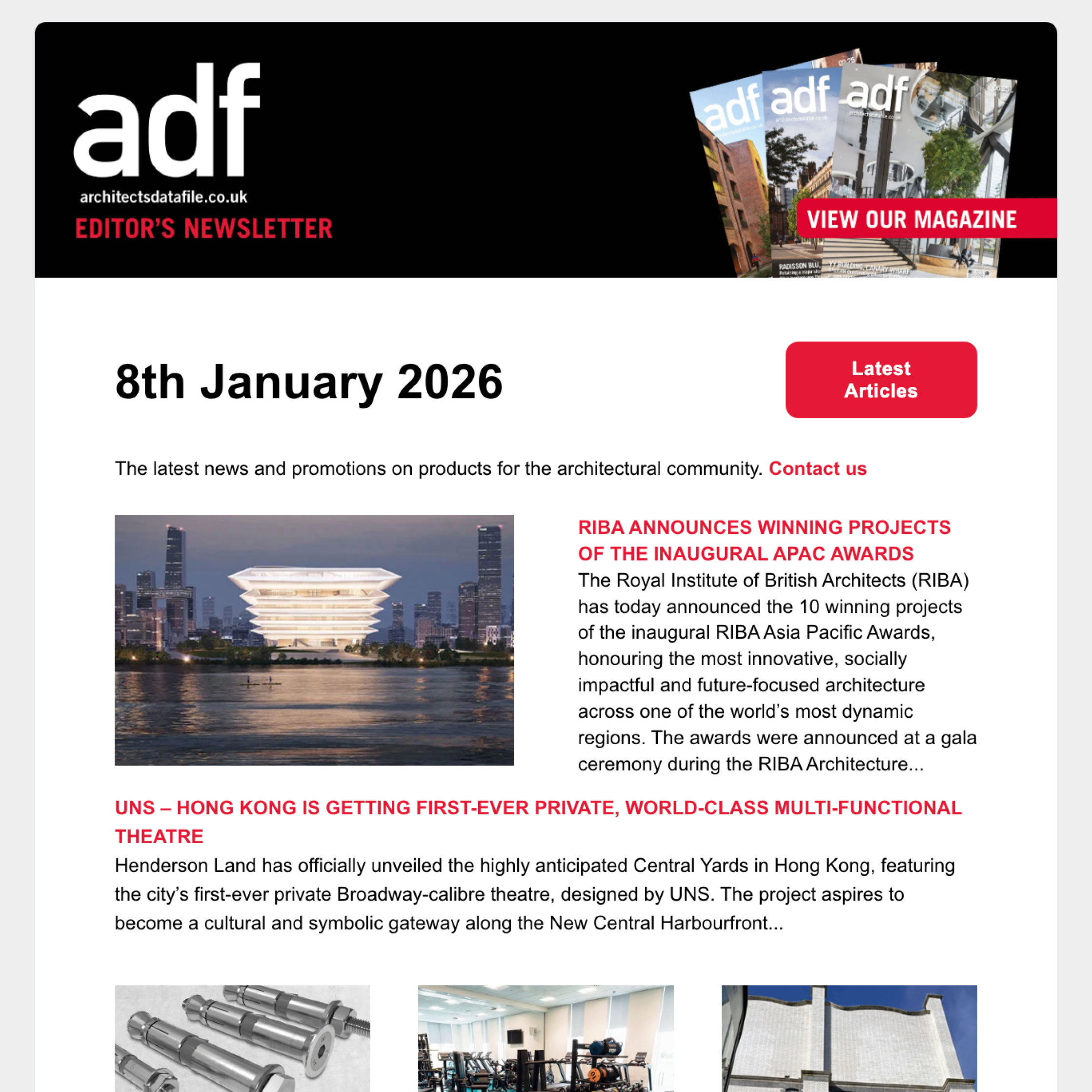

A major new residential building in Bristol is defined by its 170m long facade, clad in Nordic Brown Light pre-oxidised copper – adding a warm, naturally developing character and complementing its modern, listed neighbour.

Designed by Ferguson Mann Architects (FMA), the Copper Building is the second phase of Bristol’s Lakeshore residential development for Urban Splash, set in 10 acres of established landscape surrounding a lake. It follows FMA’s redevelopment of the iconic Grade II listed former headquarters of Imperial Tobacco, designed during the 1970s in the International Style by Skidmore, Owings and Merrill (SOM).

The new Copper Building replaces the SOM-designed factory, demolished in the 1990s, and provides 136 apartments for rent or for sale, including purchase through Shared Ownership. Project architect Nick Brown explained FMA’s design strategy:

‘The factory building that occupied the northern edge of the site was particularly significant, not just for the local area but Bristol as a whole. Without it, the northern edge of the site felt incomplete and it was an obvious decision to create a new building, enclosing the parkland and addressing the street and retail park to the north.

‘The form and language of the Copper Building were always intended as a reference to its Cor-ten steel clad predecessor. Although our initial design included Cor-ten steel cladding, as it developed, we sought a more friendly and economic material to speak of the industrial heritage of the site, yet in a warmer and more refined way – a material with some life, that would patinate subtly over time. The warm colour of the Nordic Brown Light pre-oxidised copper, along with the longevity, sustainability and natural credentials of copper made it the perfect choice.

‘The rigorous 3.6m wide structural grid that defined all elements of the SOM-designed, Mies-inspired Phase 1 building was a key driver in the design of the Copper Building. The lake frontage is an open grid of timber-clad balconies with generous glazing. However, the street and end facades are more varied with a mix of 3.6m, 7.2m and 10.8m ‘design bays’, defining a mix of 1-bed, 2-bed and duplex apartment types. A particular design challenge was to bring some fun and visual interest to the street facade of a building that is 170 metres long. Here, the apparently random fenestration belies an underlying structure of bays and rhythmic pattern of windows and vertical seams in the copper cladding that tie everything together. The Nordic Brown Light copper cladding also continues on into the fully-glazed central atrium.

‘Key to the success of the building was the precise detailing and execution of the Nordic Brown Light copper cladding. For example, we avoided a crude coping on the top and instead developed a concealed parapet cladding detail so that the vertical seams silhouette against the sky, yet still achieve a robust roof-edge detail. At the outset of the project, the installer set out a full-size cladding bay to identify potential issues with FMA, allowing details to be refined. The new Copper Building still maintains a dialogue with the neighbouring Cor-ten clad Lakeshore building and they both sit comfortably together, just as the original factory and office did. Importantly, local feedback about the building has been really positive’.

Nordic Brown Light is part of an extensive portfolio of architectural copper surfaces and alloys from Aurubis, with an unrivalled lifespan, no maintenance and full recyclability. With a melting point of 1083˚C and ‘A1 (non-combustible material)’ fire classification to EN 13501-1, copper is suitable for cladding tall buildings, using appropriate constructions.

Choices include Nordic Standard ‘mill finish’ and Nordic Brown pre-oxidised copper offering lighter or darker shades of brown determined by the thickness of the oxide layer. The extensive Nordic Blue, Nordic Green and Nordic Turquoise ranges have been developed with properties and colours based on the same brochantite mineralogy found in natural patinas all over the world. As well as the solid patina colours, ‘Living’ surfaces are available for each with other intensities of patina flecks revealing some of the dark oxidised background material.

Copper alloys include Nordic Bronze and Nordic Brass, which can also be supplied pre-weathered. The innovative Nordic Royal is an alloy of copper with aluminium and zinc, retaining its golden colour. A wide choice of Nordic Decor mechanically applied surface treatments is also available.

Nordic Copper is produced by Aurubis, part of the world’s leading integrated copper group and largest copper recycler. For more information visit: www.nordiccopper.com or email: g.bell(Replace this parenthesis with the @ sign)aurubis.com