Metal mesh is an extremely versatile product and can be used for a variety of different applications. Although common uses of metal mesh include balustrade infill panels, façade systems, or the ubiquitous radiator grille, they are now also a popular choice for ceiling tiles. Although choosing a pattern of metal mesh that looks attractive is easy, the crucial element is understanding if the mesh pattern is suitable for your application, because different patterns and specifications of metal mesh may only be used for certain applications.

Suspended ceilings were first introduced around 100 years ago, they were a novel idea to hide building infrastructure such as ducting and pipework and creating a space to allow access for maintenance – this is where the mineral fibre tile came in as the most cost effective way of creating the suspended ceiling. They were cheap, and relatively good acoustically. However, now with the option to use metal mesh in ceilings, it allows a suspended ceiling whilst offering benefits including improved airflow, lighting and vastly improved aesthetics.

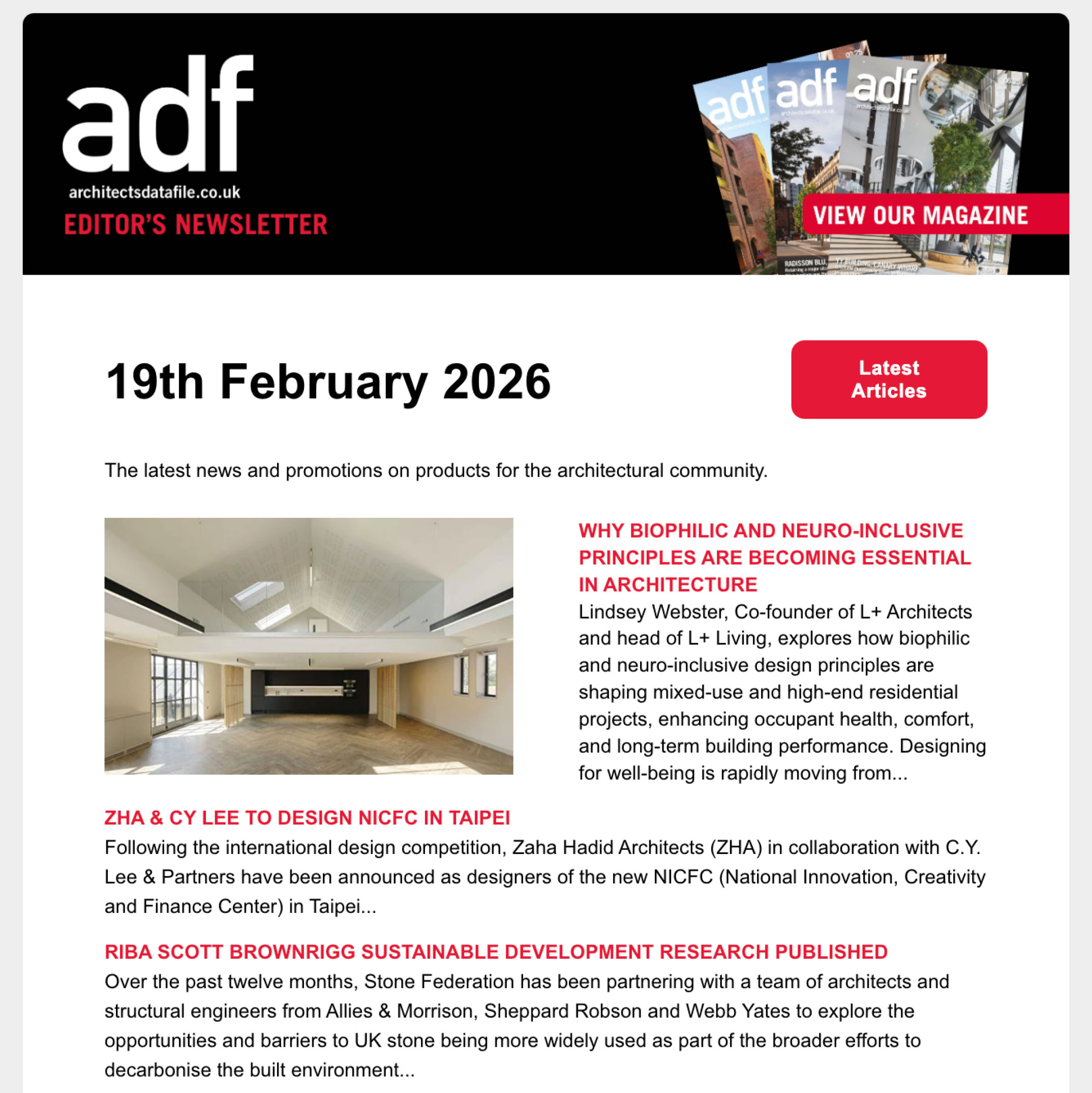

In the past, ceilings would not have necessarily been considered within the design aesthetics of a commercial space. The need for a ceiling is obviously vital, but the look and style may often have been overlooked.

Architects and Designers are looking at more inspirational approaches to the ceiling space. The demand for creating more inviting spaces and the inclusion of a well-considered ceiling can completely transform the character of a room. Amongst these approaches, we are seeing an increase in the use of metal meshes both from a point of view that they are generally made from recycled material in the case of aluminium and steel – but also the style and look of them has that upcycled feel that we are all trying to be more conscious of.

There are two categories that metal mesh falls into and these are Rigid and Flexible. Within these two categories there are multiple applications that the meshes can be used for and understanding which type of mesh can be used for which application is extremely important when specifying mesh in a project.

Rigid mesh, such as pre-crimped woven mesh, expanded mesh and perforated sheet are ideal for ceiling panels. Ceiling panels can be manufactured or fabricated into predesigned shapes and sizes. Rigid mesh also lends itself to being powder coated or anodised due to its inherent stiffness.

When designing modern spaces, it is almost unanimously agreed that sustainability is key. With the use of recycled and ethically sourced products, we are seeing that ceilings are now being designed to relate to this approach. Instead of using a product such as a mineral fibre tile which although very affordable, can crack, stain and mildew in time, thus needing to be replaced, not to mention the aesthetic impact a tired and dilapidated fibre tile has on a room.

Mesh ceilings can be either manufactured as modular tiles or bespoke to size or shape. The nature of the tile makes them stiff, light and easy to install with no extra tensioning or bracing as it is often needed with the flexible meshes. They are also incredibly hard wearing and can withstand impacts far better than a fibre board tile, and with minimal maintenance needed.

By Anthony Millington, Business Development Manager at Amron Architectural