A year on from the latest, and highly significant, changes to Part L in England, Chris Pateman of Engineered Panels in Construction (EPIC), explores why the current requirements are so important, and what specifiers need to know going forward now that the transition period has ended

After sitting in the doldrums for almost a decade, Part L of the Building Regulations finally got an overhaul in June 2022 and set us back on the path towards a net zero carbon built environment – a target that new non-domestic buildings were originally planned to meet by 2019.

With a 27% reduction in emissions over the 2013 standard being required at this stage, there is still a long way to go before hitting net zero, however there were some important changes introduced in the most recent update that will help to pave the way to that goal. This article explores the requirements that directly relate to the building envelope for non-domestic buildings, but full guidance on all aspects can be found in Approved Document L2 2021 (ADL2).

There was previously a loophole in the transitional arrangements which allowed developers to continue to build to the previous standards, provided work had started on one building before the end of the transition period. This meant phased projects and developments of multiple buildings could continue to be built to a lower standard. Under the new requirements, any buildings not started within the transition period are subject to the current regulations. The transition period to ADL 2021 finished in June 2023, so all new construction must now meet

this version.

Improvements in insulation – what changed?

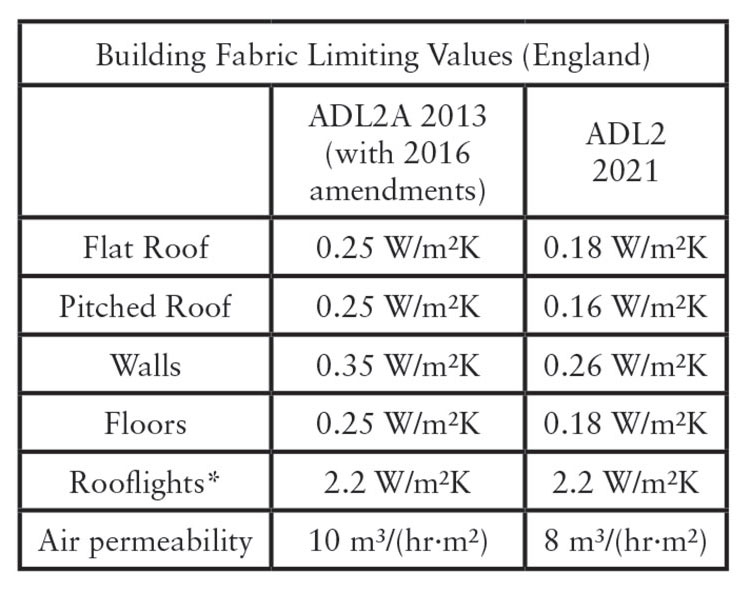

Previously the building fabric limiting values were not particularly demanding, and in most cases, buildings needed to meet the much more rigorous values set out in the notional building models to achieve compliance. The 2021 minimum U-value requirements now more closely reflect those of the notional building, and the maximum allowable ‘backstop’ level of air permeability has also been tightened.

(Note that rooflights were previously measured in the vertical plane and are now measured in the horizontal plane)

The same limiting values apply for new and replacement elements in existing buildings in England.

Measuring compliance

The National Calculation Methodology (NCM) remains the means by which compliance must be demonstrated, with an updated version of the Simplified Building Energy Model (SBEM) available to calculate aspects such as the Target and Building Emission rates (TER/BER) as well as the Target and Building Primary Energy Rates (TPER/BPER).

The introduction of the Primary Energy rate as an additional metric by which performance is measured was one of the most notable changes. The metric applies a fuel factor adjustment to the energy used, accounting for upstream activities to prepare the fuel for use, this includes steps such as extracting, refining and transporting fossil fuels. The primary energy demand for a building also factors in the fabric performance of the building and the efficiency of the heating technology used.

Carbon emissions were also retained, allowing some consistency in the benchmarking process – both metrics must be met for a building to comply.

Interestingly, amendments were introduced in February 2023 to remove the Primary Energy factor as a performance standard where district heat networks or community heating is being used. Buildings with a useable floor area of 500 m2 or more must be subjected to pressure testing to assess air permeability.

As the building envelope becomes more efficient, thermal bridging becomes a more significant factor, so ADL2 (England) requires accurate calculations of the psi values at junctions and penetrations, with a 50% penalty if assumed psi values are used instead of project specific calculations. To support this approach accredited details were removed.

Complying with Part L

Steel faced PIR core insulated panels readily achieve the required U-values with minimal thickness. For example, the minimum U-value for a flat roof is 0.18 W/m2.K, 0.16 W/m².K for pitched – a typical trapezoidal insulated panel can achieve 0.16 W/m2.K with just 120 mm thickness. The single unit panels ensure insulation continuity, and manufacturers can often provide detailed psi values to use in building energy modelling, helping to avoid penalties.

Chris Pateman is general secretary at EPIC