Ashley Cooper of WMS explains why underfloor heating is a key way to improve indoor air quality and reduce airbourne pollutants, while also providing a cost-effective way of mitigating overheating in homes

While soft furnishings are typically known as the main culprits for harbouring dust mites, skin cells and dander, convection heating systems and forced air systems are also a magnet for dust and germs which gather behind and inside the panels. Then, when a convection heating system is turned on, it often causes air to circulate more aggressively, and the problematic particles are encouraged to circulate into the atmosphere. When dust, allergens, and other particles are distributed throughout the space, it can exacerbate symptoms for those who suffer from allergies or respiratory conditions.

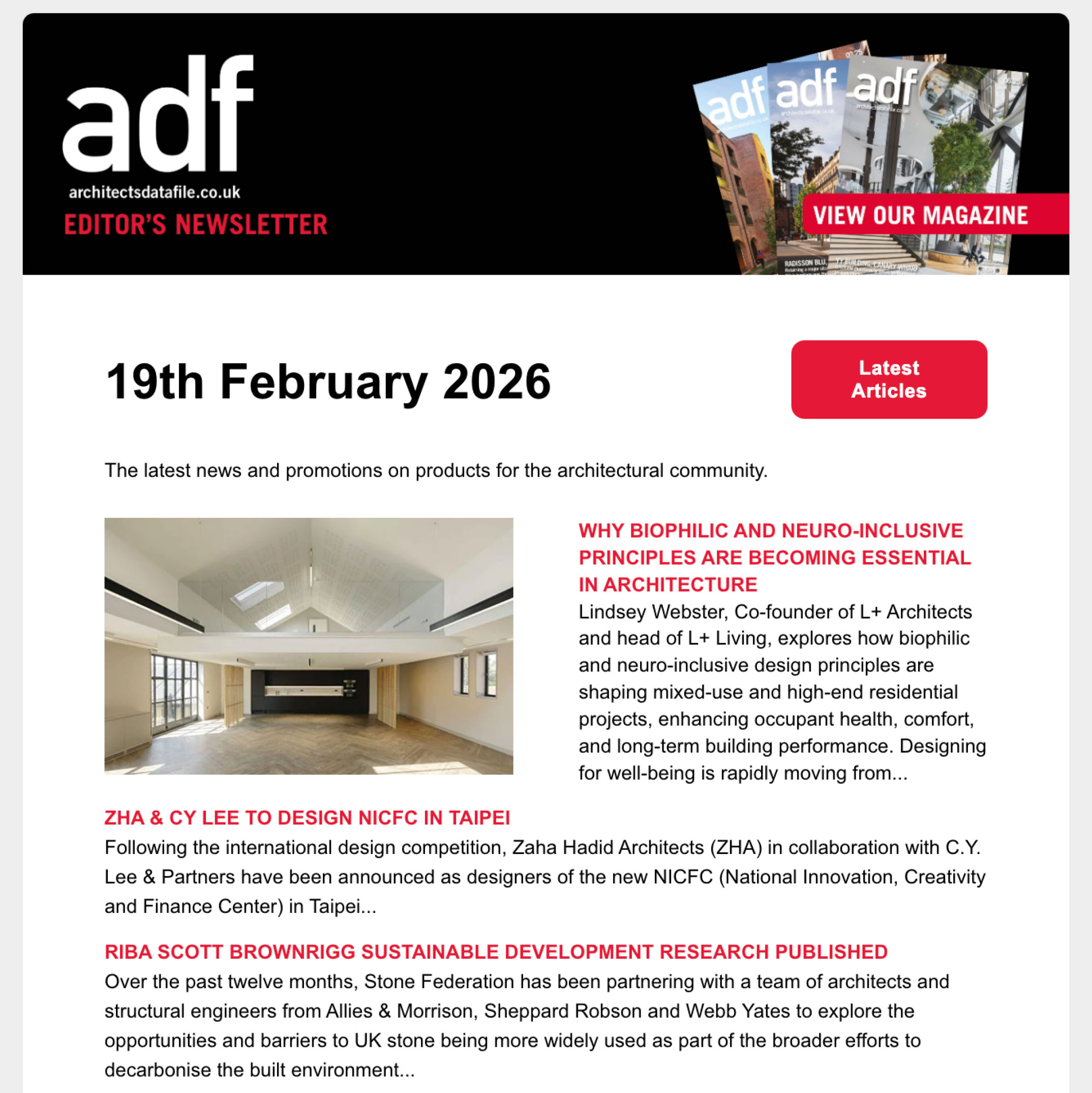

This is just one of the issues that underfloor heating can help with, as radiant heat reduces the movement of dust, making it one of the healthiest ways to heat a building. Radiant heat eliminates air movement from the heating system as it warms the fabric of a room. It doesn’t use air as a medium to transport heat, so it minimises the movement of dust and allergens. This leads to a cleaner and healthier environment.

Even heat distribution

If a traditional heating system isn’t well designed, hot and cold spots can be found within a room, leading to uneven temperature distribution. Cold spots within a space can cause condensation on walls and windows, leading to dampness and potential mould growth, negatively impacting indoor air quality. Mould not only adds to property maintenance requirements, but also exacerbates respiratory conditions.

Ventilation isn’t always the answer, as during the colder months, with energy conservation remaining at front of mind, having windows and doors open for long periods is an unlikely option. In any case, condensation will still appear if warm, moist air contacts a cold surface in the home that’s below the dew point, even with ventilation.

Underfloor heating provides a solution, as the series of continuous loops fitted under a floor create a large radiant surface that heats a room from the floor upwards. This delivers even heat distribution across the entire room, helps prevent the formation of cold spots where moisture can accumulate, and minimises the likelihood of damp conditions leading to poor air quality.

The physics of underfloor heating also means that such systems provide a more stable and consistent temperature, which helps maintain balanced humidity levels – just another way that radiant heat helps to create healthier and more comfortable living environments.

A multifunctional solution

With summers becoming hotter, homes are at increasing risk of overheating.

Part O of the building regulations defines requirements for mitigating overheating in new residential buildings.

An emerging solution is an underfloor heating system combined with a heat pump but run in reverse, to offer a passive or near-passive means of heat removal. The system requires no additional or special components apart from a control system that is designed for cooling as well as heating.

Radiant cooling provides a fresh perspective on indoor climate control and aims to work entirely in harmony with nature rather than against it. Instead of forcing cold air out, radiant cooling works by using cold surfaces to remove the heat radiated from objects within a room. We recently published our Part O research paper, ‘UFH? That’s Cool,’ which further explores the potential of UFH systems to help the industry meet the requirements of Part O of the Building Regulations.

Sustainability from the ground up

When it comes to underfloor heating pipework, the sustainable choice is superior-quality PE-RT (polyethylene of raised temperature resistance) pipe, which is composed of five bonded layers. Polyethylene has excellent properties at high pressures and temperatures, as well as being very flexible and easy to use. It is non-corrosive, has very good resistance to frost, and has a high impact strength. It’s also ‘creep-resistant’ and contains an integral EVOH oxygen barrier layer to prevent water oxygenation inside the system.

PE-RT pipe is designed to be environmentally friendly. It can be melted down to be used again or recycled. In contrast, PEX pipework, which contains toxins and can only be burnt or buried due to the molecular cross-linking process.

Some PE-RT pipes also come with a product warranty of up to 50 years, offering specifiers, housebuilders and homebuyers alike peace of mind in the quality and durability of the products. However, if the pipe is not disturbed during its use, it is expected to outlive the life of the building itself, further enhancing a building’s sustainability credentials.

Ashley Cooper is managing director at WMS