Flooring in education is becoming a question of aesthetics, with schools and colleges giving more consideration to its importance in creating inspiring learning environments. Jake Parks of IVC Commercial explains how great design plus safety and practicality can be achieved in sheet vinyl floor installations

Educators are aware of the importance interiors have in creating an environment that supports its students and encourages learning. The use of colour psychology to support activity – green for contemplation and concentration, yellow for creativity and blue for productivity – is increasingly commonplace, and biophilic, natural design is being employed to relax and calm students. Opportunities to exploit these practical applications of colour and natural design in the floor are plentiful. Examples inclue zoning in classrooms in primary education or the use of green and natural finishes in a secondary school library.

But outside of design, there are other factors that affect the floor’s suitability for education environments. Its ability to combat acoustics or improve safety – or both for that matter – while providing a finish that’s durable and easy to maintain are important factors for a floor that’s fit for purpose. And for many schools and colleges, these factors hold more sway in the decision-making process than just choosing the right shade of green or yellow. Rightly, practical considerations dominate the floor selection process, but that’s not to say it should be at the expense of achieving a design that can support learning with focus on the given activity within that area.

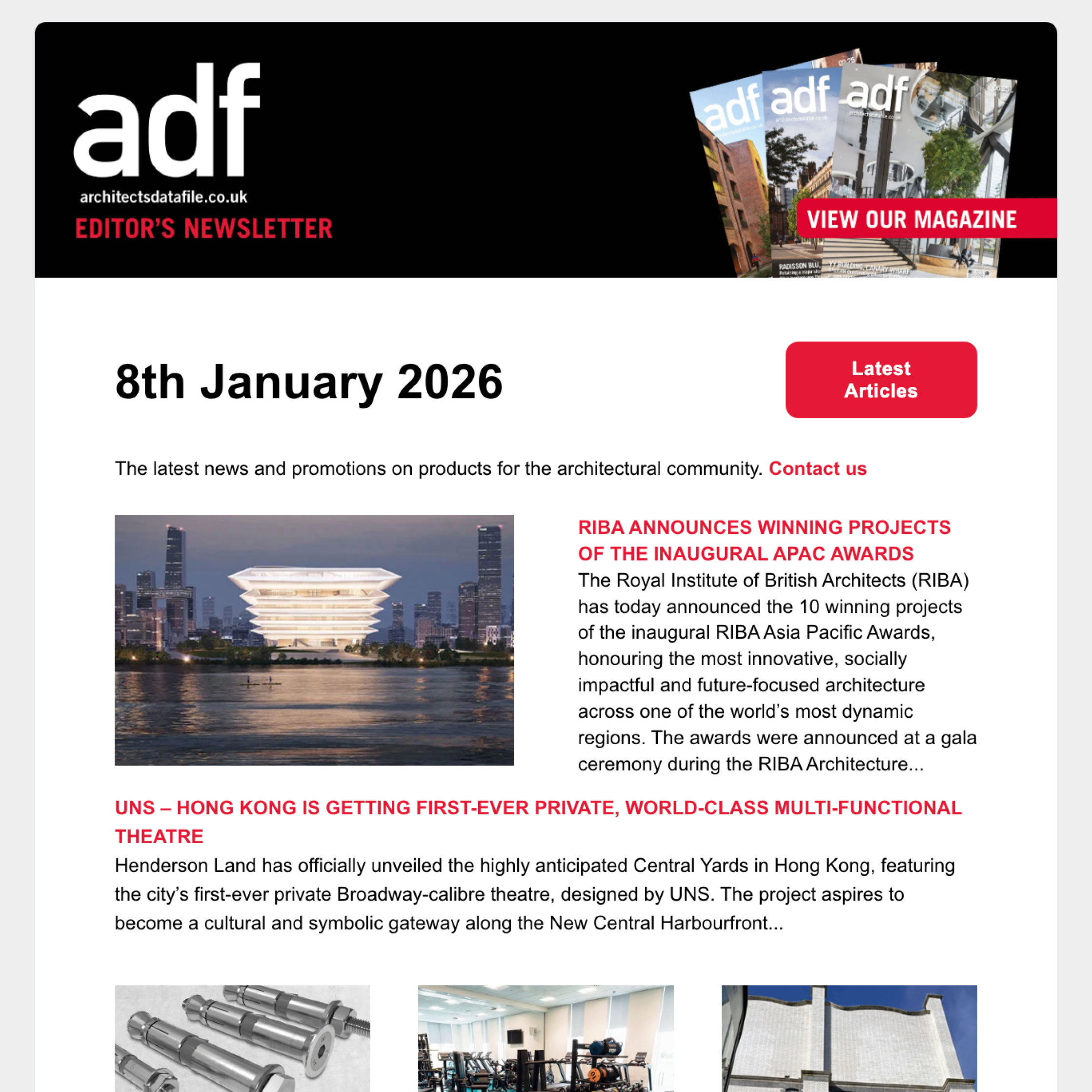

Sheet heterogeneous vinyl flooring is a popular choice in schools and colleges because of its practical advantages. It also presents design flexibility, giving the opportunity to achieve a functional finish that can also contribute to a focused, supportive learning environment. Whether zoning in colour for areas of learning or creating contrast to help with navigation, sheet vinyl flooring delivers a finish that’s hardwearing and easy to clean. Easy to cut to shape, it can also be used to create a floor with a design that adapts to specific requirements, such as a quiet reading zone in a primary classroom.

However, mixing different designs in this way is not without its challenges. The seam has always been considered something of a weak point in sheet vinyl installations, so the natural course of action is to minimise occurrence using an ‘all over’ finish that eliminates a potential failure hot spot unless absolutely necessary. While this may be a ‘safer’ route functionally speaking, it is not the best way to ensure the environment is as supportive as it can be for pupils.

So, how can durability, ease of maintenance and design integrity be achieved with sheet vinyl flooring? By changing the method of installation.

Bonding

A method of creating seams is available that eliminates the weld rods and visible joins of hot welding. Sometimes referred to as cold welding, our technology Invisiweld uses a chemical bond between each sheet, rather than introducing a third element – the weld rod – that relies on heat to create a bond between it and the two adjoining sheets.

By nature, the weld rod is a weak link in the floor installation. A pure PVC construction is ultimately less durable and harder to maintain than the PU protected floor finish and so it is often the first point of failure, or at least it begins to show wear and dirt in advance of the rest of the floor. It’s also not uncommon for hot welded seams to separate from sheets over time due to atmospheric movement – the weld rod and sheet vinyl are two different materials – and constant heavy traffic also stresses the joint. In many instances, failed hot welded seams will compromise an otherwise fully functional floor well before it needs replacing.

A direct chemical bond ‘fuses’ the sheets together so they become a whole, single piece. By eliminating the weld rod, this method is not only far less likely to fail, but it also allows seams to be introduced with less risk so that a better floor design can be achieved. Allowing the installation of sheet vinyl in shapes, colour combinations or indeed almost anything that can be imagined, such a method brings durability and design integrity.

The resulting join is almost imperceptible to the human eye, so even in ‘all over’ installations of a single design or colour it brings a better look. Whether it’s a herringbone wood design or a concrete effect, the elimination of a visible seam makes the floor look more authentic.

In short, from both a performance and aesthetic standpoint the approach is superior. Installation is also no more time intensive than hot welding and it is safer too. With hot weld torches operating at a temperature of over 300°C, severe burns are a real risk in operation and a constant power source is required. Getting rid of both of these provides an installation that’s safer and easier to implement across a range of environments and build phases. Eliminating the mess and off-cuts of unused weld rod, it makes for a cleaner install and can also be used to join heterogeneous sheet vinyl with our luxury vinyl tiles.

For schools and colleges looking to embrace a more focused approach to the design of the floor, then sheet heterogeneous vinyl installed using a chemical bond method makes complete sense. Indeed, even if a varied layout isn’t required, such a solution is still sensible – and one that offers advantages for both the installer and education environment.

Jake Parks is commercial business manager at IVC Commercial